Warehouse Conversion to Highly Bespoke Production Facility.

By Glenside, Reading.

Andover

30 weeks

36,000 sq ft

Electronics Manufacturer

Intricate design.

High quality and detailed design was absolutely key to the success of this project. Taking into account coordination of structural aspects, building regulations, landlord requirements, cleanroom compliance standards, health and safety, designs by client-appointed specialists, process / personnel flow and energy conservation, Glenside acted as CDM Principal Designer and also managed Building Control approval.

Technical CAD drawings were produced and regularly updated throughout the project to accommodate the client’s evolving needs.

Fit-out of a new specialist electronics facility.

This project saw us develop a basic new-build warehouse-type property into a fully

operational technical electronics facility.

Our client selected us to provide a design and build process, spanning from initial concept

design, via detailed design and specification, and through to installation and handover.

Existing spaces and new mezzanine space were professionally developed into a modern

and professional industry-leading space, delivered on time and on budget.

Fit-out of specialist electronics facility.

This project saw us develop a basic new-build warehouse-type property into a fully operational technical electronics facility.

Our client selected us to provide a design and build process, spanning from initial concept design, via detailed design and specification, and through to installation and handover. Existing spaces and new mezzanine space were professionally developed into a modern and professional industry-leading space, delivered on time and on budget.

Take a tour:

Intricate design.

High quality and detailed design was absolutely key to the success of this project.

Taking into account coordination of structural aspects, building regulations, landlord requirements, cleanroom compliance standards, health and safety, designs by client-appointed specialists, process / personnel flow and energy conservation, Glenside acted as CDM Principal Designer and also managed Building Control approval.

Technical CAD drawings were produced and regularly updated throughout the project to accommodate the client’s evolving needs.

Precise fulfilment.

From preparatory works and the erection of a new mezzanine floor through to final finishes and commissioning, Glenside acted as the CDM Principal Contractor.

Our office-based operations team worked closely with our dedicated site manager and supervisors to ensure a high quality result delivered in line with the programme.

This involved working in conjunction with the client’s appointed specialists for certain aspects of the work to deliver a seamless project. Precision was called for, especially in the creation of a certified air-tight cleanroom construction with its host of specialist services.

Intricate design.

High quality and detailed design was absolutely key to the success of this project.

Taking into account coordination of structural aspects, building regulations, landlord requirements, cleanroom compliance standards, health and safety, designs by client-appointed specialists, process / personnel flow and energy conservation, Glenside acted as CDM Principal Designer and also managed Building Control approval.

Technical CAD drawings were produced and regularly updated throughout the project to accommodate the client’s evolving needs.

Precise fulfilment.

From preparatory works and the erection of a new mezzanine floor through to final finishes

and commissioning, Glenside acted as the CDM Principal Contractor.

Our office-based operations team worked closely with our dedicated site manager and supervisors to ensure a high quality result delivered in line with the programme.

This involved working in conjunction with the client’s appointed specialists for certain aspects of the work to deliver a seamless project.

Precision was called for, especially in the creation of a certified air-tight cleanroom construction with its host of specialist services.

Precise fulfilment.

From preparatory works and the erection of a new mezzanine floor through to final finishes and commissioning, Glenside acted as the CDM Principal Contractor.

Our office-based operations team worked closely with our dedicated site manager and supervisors to ensure a high quality result delivered in line with the programme. This involved working in conjunction with the client’s appointed specialists for certain aspects of the work to deliver a seamless project.

Precision was called for, especially in the creation of a certified air-tight cleanroom construction with its host of specialist services.

Variety of functions.

This project included construction of an 8,000sqft ISO7 certified cleanroom and a full range of other spaces, including changing room, transfer room, stores, washrooms, canteen, reception, boardroom, offices and external compressor building.

The primary focus was on functionality and compliance, but finishes were co-ordinated to provide a smart and modern feel to the entire space.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

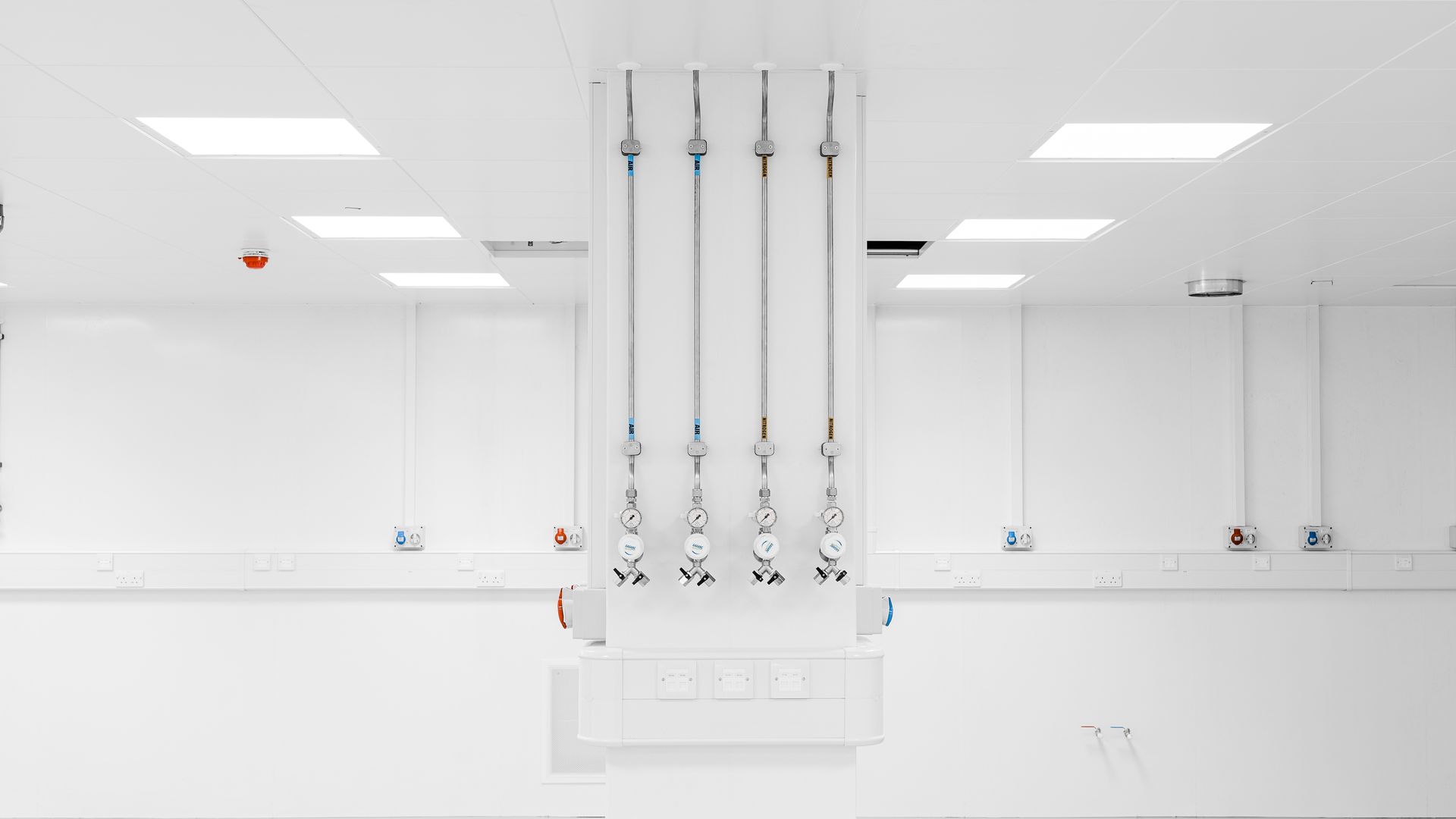

Specialist scope.

Specialist aspects of the project included design and installation of:

- Mezzanine floor

- Compressed air system

- Nitrogen services

- Oxygen depletion monitoring

- Fire and security systems

- ESD flooring

- Fire rated partitions, windows and doors

- Internal and external drainage

- Air-tight sealed walls and ceilings

- Ventilation and air conditioning

- Specialist door sets

- External plant compound / compressor building

Specialist scope.

Specialist aspects of the project included design and installation of:

- Mezzanine floor

- Compressed air system

- Nitrogen services

- Oxygen depletion monitoring

- Fire and security systems

- ESD flooring

- Fire rated partitions, windows and doors

- Internal and external drainage

- Air-tight sealed walls and ceilings

- Ventilation and air conditioning

- Specialist door sets

- External plant compound / compressor building

Specialist scope.

Specialist aspects of the project included design and installation of:

- Mezzanine floor

- Compressed air system

- Nitrogen services

- Oxygen depletion monitoring

- Fire and security systems

- ESD flooring

- Fire rated partitions, windows and doors

- Internal and external drainage

- Air-tight sealed walls and ceilings

- Ventilation and air conditioning

- Specialist door sets

- External plant compound / compressor building

Before & After.

A spacious new production facility.

More of our projects:

Get in touch.

For more details on how we can help or to book a consultation at our

showroom, please call us on

0118 214 7890

or fill out the form and we will get back to you soon.

Contact Us

We will get back to you as soon as possible.

Please try again later.

Quick links.

Glenside Commercial Interiors is a trading name of Glenside Commercial Interior Projects Limited registered in England with Registration Number 14000423. VAT No. 408 5792 72

All Rights Reserved